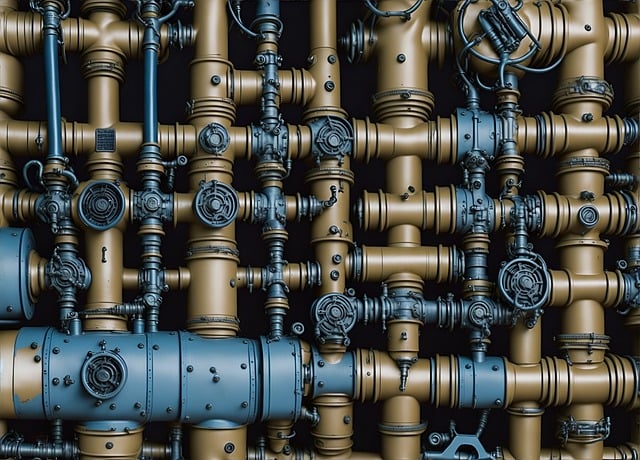

Cold weather plumbing faces significant threats from frost heave and temperature swings, exacerbated by heavy rainfall and humidity. To mitigate risks, seasonal maintenance is crucial. Strategies include improving drainage, using corrosion-resistant materials, applying protective coatings, insulating pipes in extreme zones, and promptly repairing damage to safeguard against pipe corrosion during harsh conditions. Regular inspections are essential for identifying and resolving issues before they escalate.

In regions with extreme cold and variable weather patterns, frost heave poses a significant threat to underground pipes. This natural phenomenon, driven by rapid temperature changes, can cause pipes to lift, bend, or even burst, leading to costly damage. Understanding the mechanisms behind frost heave is crucial for mitigating its effects. This article explores ?cold weather plumbing issues, delving into how heavy rainfall and humidity interact with temperature fluctuations to compromise pipe stability. We also provide insights on seasonal maintenance practices and strategies to prevent pipe corrosion in extreme conditions.

- Understanding Frost Heave: A Common Cold Weather Plumbing Issue

- How Heavy Rainfall and Humidity Affect Underground Pipes

- Seasonal Maintenance: Preparing for Temperature Fluctuations

- Preventing Pipe Corrosion in Extreme Conditions

Understanding Frost Heave: A Common Cold Weather Plumbing Issue

Frost heave is a common yet often overlooked issue in cold weather plumbing, caused by temperature fluctuations and humidity effects during the winter months. When the ground freezes, it expands, pushing upward against underground pipes. This can lead to pipe distortion, cracks, or even bursts, particularly in areas with heavy rainfall impact. The severity of frost heave is directly proportional to the degree of temperature drop and the moisture content in the soil.

Regular seasonal maintenance is crucial to mitigating the risks associated with frost heave. Ensuring proper drainage around pipes can help reduce moisture levels in the ground, while insulating pipes against extreme cold temperatures can prevent corrosion and damage. By addressing these factors, homeowners and professionals alike can better protect their plumbing systems from the perils of cold weather, ensuring smoother operations year-round.

How Heavy Rainfall and Humidity Affect Underground Pipes

In colder climates, heavy rainfall and high humidity can significantly impact underground pipes. When water seeps into the ground, it expands as it freezes, causing soil to swell and contract with temperature fluctuations. This process, known as frost heave, exerts pressure on pipes, leading to potential damage or misalignment. Pipes made of metal or other vulnerable materials are particularly susceptible to corrosion and cracking under these conditions.

Seasonal maintenance is crucial for addressing the effects of heavy rainfall and humidity. Regular inspections can identify any signs of pipe movement or damage caused by frost heave. Preventive measures such as insulation and protective coatings can help mitigate the impact of temperature changes, reducing the risk of pipe corrosion and ensuring the stability of underground plumbing systems throughout the year.

Seasonal Maintenance: Preparing for Temperature Fluctuations

In regions prone to cold weather and significant variations in temperature, seasonal maintenance is a critical aspect of ensuring the stability and longevity of underground pipes. As winter approaches and temperatures drop, pipe corrosion becomes a significant concern. Frost heave, a phenomenon where frozen ground expands and contracts, can exert immense pressure on buried pipelines, leading to potential damage or dislodgement. To mitigate these risks, regular inspections and maintenance checks are essential. This includes identifying and repairing any leaks or cracks that might have developed during the previous season.

During seasonal transitions, heavy rainfall can also contribute to increased humidity levels near the ground surface, accelerating corrosion processes. Therefore, a comprehensive maintenance routine should involve treating pipes with protective coatings or linings resistant to both cold and moisture. By preparing for temperature fluctuations and implementing proactive measures, ?cold weather plumbing issues can be minimized, ensuring the reliable operation of underground pipelines even in challenging environmental conditions.

Preventing Pipe Corrosion in Extreme Conditions

In cold weather plumbing scenarios, pipe stability becomes a paramount concern due to ?cold weather plumbing challenges like frost heave and temperature fluctuations. These conditions can lead to significant stress on underground pipes, potentially causing corrosion over time. Heavy rainfall impact and increased humidity further exacerbate the issue by introducing moisture that accelerates corrosion rates. To mitigate these effects, regular seasonal maintenance is crucial.

Pipe corrosion prevention strategies include ensuring proper drainage around pipes to minimize water accumulation, using corrosion-resistant materials where feasible, and applying protective coatings or linings. Additionally, insulating pipes in areas prone to extreme temperatures can help maintain consistent temperatures, reducing the risk of frost heave. Regular inspection and timely repair of any damaged sections are also essential components of ?cold weather plumbing care.